PC-based control is ideally suited to the complete automation of many different processes in the wood industry. The bandwidth of solutions ranges from complete sawmills to individual machines for joiners and smaller businesses, and even fully automated furniture production with interlinked systems consisting of transport, feeding/stacking, edge processing, CNC machining, and surface treatment. PC-based control – our drastically simplified control structure combined with the consistent use of IT standards – meets the demand for maximum part throughput with a high degree of individualization, fulfills the highest quality requirements, and responds to intense cost pressure. Fast and high-performance control technology from Beckhoff ensures that our furniture manufacturer customers and their machine building partners are well-equipped to tackle the challenges they face.

Securing your competitive edge in woodworking with Beckhoff:

- end-to-end solution for all processes in the wood industry

- cost-efficient system automation through flexible scalability of all hardware and software functions

- higher system availability and reduced complexity through consolidation of PLC, motion control, NC/CNC, robotics, HMI, vision, AI, and specific machine learning algorithms

- maximum freedom in machine design thanks to open interfaces in hardware and software

- a reliable partner with decades of experience in the woodworking industry

High-performance control technology for all sectors of the wood and furniture industry

Our technologies for your woodworking machine

All functions integrated on a single platform

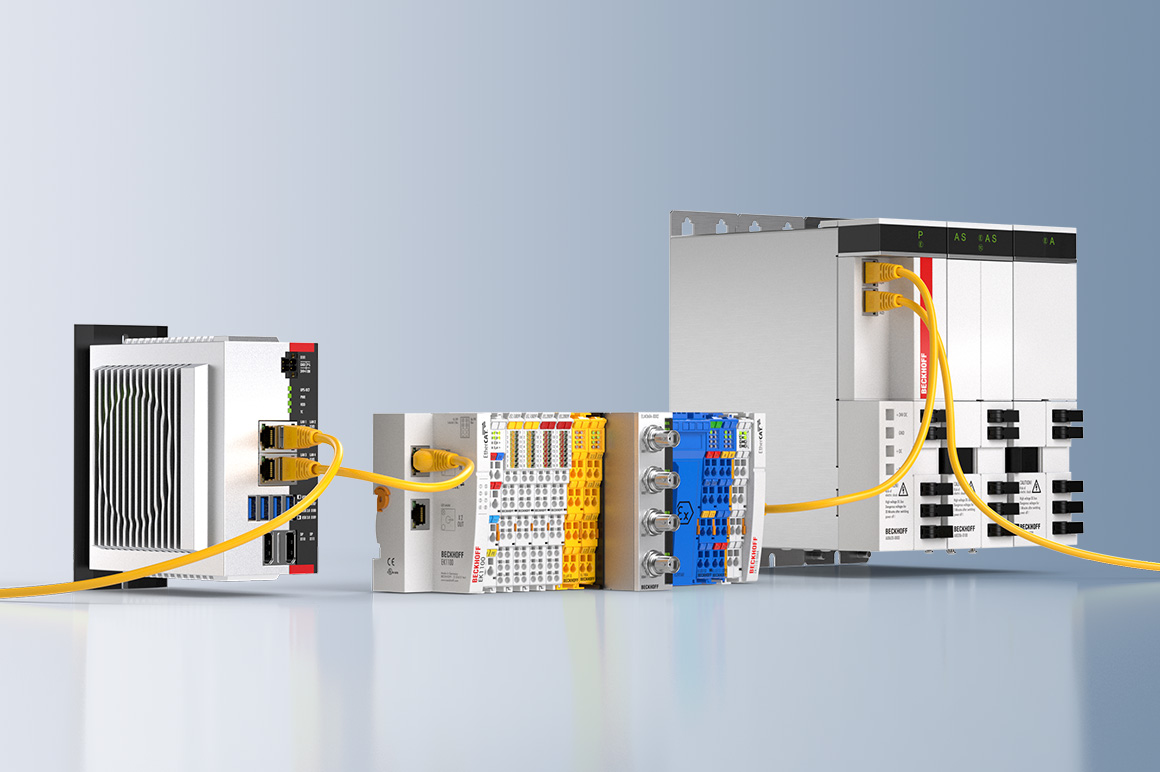

PC-based control facilitates the significant optimization of woodworking in terms of both productivity and efficiency. Our scalable and powerful portfolio of hardware and software enables customized control solutions – from simple sequence controls through to high-performance motion control solutions with multiple axes and auxiliary drives. Scalable industrial PCs form the backbone of the system, complemented by the modular and real-time-capable TwinCAT software architecture, along with EtherCAT as a powerful communication system. PC-based control provides you with a future-proof solution:

The core advantages of PC-based control:

- open: from the integration of your process expertise through to cloud connectivity

- integrated: handle sophisticated CNC, motion control, and ancillary functions on a single software platform

- scalable: the application determines the performance, design, and price of the automation

- continuous innovation: Beckhoff secures your competitive edge

Uncompromisingly fast, flexible, and open

EtherCAT technology was developed by Beckhoff and made available as an open automation technology standard. EtherCAT P is 100% EtherCAT – with integrated power supply for sensors and actuators on the same cable. This further reduces the time and money spent on installation, saves space, and simplifies the modularity of machines. With outstanding performance, flexible topology selection, comprehensive diagnostics, and simple configuration, EtherCAT and EtherCAT P are also ideally suited for use in woodworking machines.

EtherCAT highlights for the woodworking industry:

- extremely fast cycle times for precise and efficient processes

- wide selection of EtherCAT-compatible sensors and actuators on the market

- flexible integration of other fieldbus systems, such as CANopen, IO-Link, PROFINET, PROFIBUS, EtherNet/IP, Modbus/TCP, TSN, OPC, etc.

- reduced cabling effort thanks to the EtherCAT P one cable solution

- maximum performance with speeds of 1 Gbit/s or 10 Gbit/s with EtherCAT G

Simplifies and accelerates engineering

The TwinCAT 3 automation software integrates all engineering and runtime processes and features a consistent development environment for implementing all control tasks in the woodworking industry. Programming is carried out using the most appropriate method for the application, including IEC 61131-3, high-level languages such as C/C++, MATLAB®, and Simulink®. Microsoft Visual Studio is used as the standard programming workbench, since it not only supports version management, but also simplifies teamwork. Ready-made software blocks, the integration of simulation tools, and powerful diagnostics facilitate engineering and shorten development and commissioning times.

TwinCAT the universal software for your woodworking machines:

- libraries for motion control, CNC, and supplements for robot kinematics

- accelerated commissioning and maintenance with TwinCAT Scope

- simplified implementation of functional safety with TwinSAFE

- cloud communication in common protocols with TwinCAT IoT

- AI-supported engineering with TwinCAT CoAgent

The modular and easy-to-integrate safety solution

TwinSAFE provides a certified safety solution to meet the safety requirements of a machine that integrates seamlessly into the Beckhoff control system. The various I/O components are certified for all safety-relevant applications in the wood industry up to SIL 3 in accordance with EN 61508:2010 and Cat 4, PL e in accordance with DIN EN ISO 13849-1:2016-06. Numerous drives with safety-related functions are also available. The safety application is configured or programmed in the TwinCAT development environment and then transferred to a TwinSAFE Logic component, which communicates with all safety devices in the system.

TwinSAFE – the advantages for your woodworking machine:

- all safety functions can programmed and configured with TwinCAT

- many TwinSAFE I/O modules available with IP20 and IP67 protection rating

- flexible mixing of safe signals with standard signals in the terminal segment

- safety logic is distributed in I/Os and drives via the EtherCAT network

- TwinSAFE SC technology enables the use of standard signals for safety-related tasks

Control and regulation in the sub-100 µs range

Some applications have extreme requirements for cycle and reaction times (position detection of workpieces in a continuous process, for example). Beckhoff’s eXtreme Fast Control (XFC) technology makes it possible to achieve the I/O response times of < 100 μs required for such tasks. It is based on an optimized control and communication architecture comprising modern industrial PCs, ultra-fast I/O terminals with enhanced real-time characteristics, the EtherCAT high-speed Ethernet system, and the TwinCAT automation software.

XFC – advantages for the woodworking industry:

- extremely short control loops with 100 µs cycle times

- fast I/O response times from 85 µs

- time synchronization of signals in the ns range

- hard synchronization of CPU, I/O, and drives through distributed clocks with 64-bit resolution

- supported by many digital and analog input and output modules

Our product highlights for your woodworking machine

Software for highly dynamic motion control

TwinCAT Motion offers scalable software packages for all woodworking processes. A wide range of options are available for controlling the uncoordinated and coordinated movements of a variety of electrical axes and drive systems. They include DC motors, stepper motors, and servomotors in the low-voltage range, as well as cost-efficient variable frequency drives and servo drives, and highly dynamic servo drives and linear motors. The new generation of motion control with TwinCAT MC3 expands the existing functions of TwinCAT NC2 (CNC, flying saw, and camming, for example) to include features such as multi-core and multi-tasking, and thus opens up further potential in terms of efficiency and speed.

Securing your competitive edge with high-performance motion modules:

- TwinCAT 3 NC PTP: basic package for motion control functions

- TwinCAT 3 CAM Design Tool and NC Camming: cam plate design and runtime libraries

- TwinCAT 3 NC Flying Saw: accurate synchronization with the master axis

- TwinCAT 3 NC I: interpolation of up to 3 main and 5 auxiliary axes per channel

- TwinCAT MC3 and TwinCAT PLC++ eliminate system limits with regard to the number of axes, different axis cycle times (multitasking), and synchronized movements across CPUs (multi-core)

Highly precise linear movements for woodworking

The AL8000 linear motor series is particularly suitable for applications with the highest requirements for dynamics, positioning accuracy, and synchronism. As there is no mechanical conversion from rotary to translatory motion, the integration of the load into the motor is backlash-free. This also allows the position measuring system to be coupled directly to the motor. The direct translatory movement of the linear motor, in combination with high-resolution position feedback, is the basic prerequisite for the implementation of high-precision machines.

Securing your competitive edge with linear drive systems for the wood industry:

- modular coil concept for extremely high force density combined with compact dimensions

- different series and widths enable a wide range of different applications to be supported

- integrated feedback system and One Cable Technology (OCT) simplify integration and assembly

- additional cogging compensation for even higher accuracy and synchronization requirements

Flexible and modular drive solutions for woodworking machines

In addition to precision and speed, the woodworking industry also requires flexible and modular drive solutions for high-performance machine concepts. This is why distributed drive technology has become a key technology. It offers significant advantages over traditional control cabinet approaches, especially in terms of flexibility, scalability, and efficiency. In distributed drive technology, the servo drives or stepper motor terminals are installed directly in the motor housing. In addition to distributed servo drives, components are available for power supply, distribution, or coupling to a conventional servo drive group.

Securing your competitive edge with distributed drive systems in the wood industry:

- control cabinet-free machine concepts

- space-saving, straightforward, and smaller footprint

- simple wiring and low installation and commissioning costs with EtherCAT P

- high level of modularity for system adaptations or extensions

- connection of additional I/O signals in IP65 configurations possible

- safety included: TwinSAFE available for all Beckhoff drive solutions

Seamless integration of machine vision

With Beckhoff Vision, real-time image processing can be easily integrated into both new and existing control environments, and can be optimally synchronized with all machine and plant processes. Example applications include detecting defects or assessing surface quality in veneer, as well as checking contours. System integration effectively bridges the historical division between vision and automation technology. At the same time, the Vision components impress with their robust, attractive design as well as high scalability and long-term availability, from the cameras to the optics and lighting units to the Beckhoff TwinCAT Vision software.

Securing your competitive edge with Vision integration in EtherCAT:

- highly precise and synchronous assignment of image processing to control processes, e.g., positions

- simplified and synchronized trigger generation for image capture and exposure

- shortened response times, higher cycle rates, and accelerated processing

- reduced hardware, wiring, waiting time, installation space, and footprint

- simplified diagnostics

Eliminate the control cabinet with the MX-System

The MX-System opens up completely control cabinet-free automation solutions. Combining various baseplates and function modules (IPC, coupler, I/O, drive, relay, pneumatic, and system modules), the modular system encompasses all the functions and properties of a control cabinet: power supply, fuse protection and power distribution, generation and monitoring of auxiliary voltages, sequence control with inputs and outputs, control of motors and actuators, and the connection level for the field devices. The internationally certified components reduce the labor required for planning, assembly, machine installation, and maintenance.

How you benefit from the MX-System for woodworking machines:

- smaller footprint due to the elimination of control cabinets

- IP67 housing to facilitate use in all areas of woodworking

- increased efficiency due to reduced engineering, assembly, and testing effort

- rapid troubleshooting with diagnostic app

- can be flexibly combined with EtherCAT Box modules and distributed servo drive systems

- integrated safety functionalities for drives and I/Os via FSoE